Features

- Combined internal and external cleaning

- Integrated detergent set (up to 5 media tanks)

- Positive internal keg transport

- Completely piped and wired

- Limited time for installation/commissioning: plug and run

- Integrated control cabinets

- Simatic S7 PLC with touchscreen control

- Double station external washer

- Transport in standard container

- Small footprint

- Remote service and diagnostic system

- Safety perimeter by glass panels

- Foam cleaning ready

- Detergent soaking time up to 5 min.

- 3 to 5 active washing heads

- One filling head with auto shut off control

Technical data

- Capacity 60 – 90 kegs/hr (depending on configuration and keg size)

- 10 till 60 l kegs, dia 235 – 430 mm, H 300 to 620 mm

- Filling accuracy +/- 1,25 % ( - +/- 0,2% with BPCU)

- CO2 loss - 0,0 – 0,1 g/l

- O2 pick up – 0,08 ppm ( / 0,05 ppm with BPCU)

- Noise level < 80 dbA

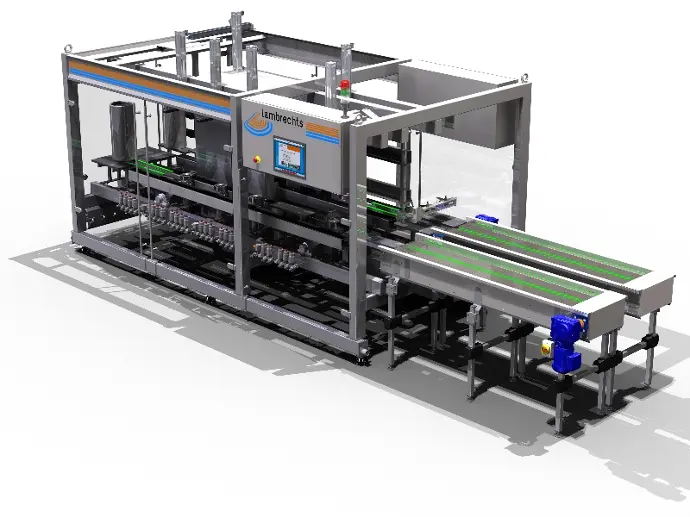

- Dimensions: L 4225 mm x W 2230 mm x H 2510 mm production (H 2200 transport)

- Weight: empty 3600 kg / production 4200 kg

- Power 230/400 V – 50/60 Hz - 4 - 12 kW (depending on configuration)

- Shipping form: one 20’ container = 1 TEU

Options

- Caustic spray on fitting and rim side

- Automatic detergent dosing system

- Flow meter with automatic back pressure control unit (BPCU)

- Allen Bradley PLC

- Auxiliary machines (weigher, turner, coder, keg conveying, palletizing)

- Integrated weighing scale

General

- 4-5 washing heads

- 1 filling head (racking)

- Up to 5 detergent tanks (standard 4)

- 2 m driven in feed conveyor / 2 m gravity out feed conveyor

- Soaking up to 5 minutes (20 minutes optional)

- Integrated hot water, detergent set & mixed water

- External washer (optional)

- Small footprint design on SS-frame